ABOUT US

-

PURBACHAL STEEL MILLS LTD. (PSML) established in the year 1999, is a proud and promising enterprise of a Purbachal Group of Enterprises. Through its farsighted vision and indomitable mission for building a new generation Steel Mill to meet the increasing demand of improved and guaranteed quality Steel Reinforcement Bars, PSML established an automatic Steel Re-Rolling unit with almost all modern facilities at a best location only 30km from Dhaka city on Dhaka-Mymensingh national highway.

From the date of its inception PSML continuously and relentlessly striving for introducing latest technological inventions and devices towards improving the mechanical properties of the steel Bars to ensure safe and earthquake proof building construction in this country.

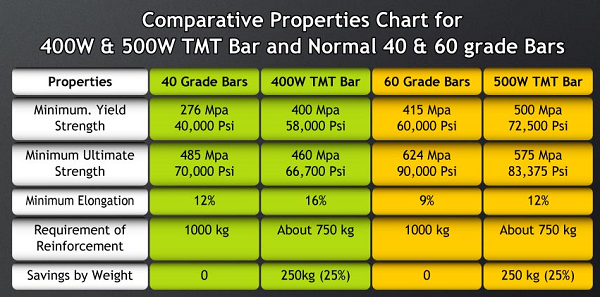

Earlier, PSML was producing Steel deformed bars conventionally known as 40 and 60 Grade Bars as per international standards but, with the recent development of TMT (Thermo Mechanical Treatment) Technology PSML has already introduced the technology to produce High Tensile Bars of 400W and 500W Grades conforming to BDS-ISO 6935, BS 4449 Grade-B500C, ASTM 706, JIS G3112 SD390 or DIN 488, which have got about 20% higher strengths. These Grades of TMT Bars have technically and economically replaced the conventional 40 and 60 Grade Steel Bars. The Comparison Chart shown hereunder speaks the truth:

See more

See more

-

TMT Bar is a thermally treated M S Bar with enhanced Surface strength combined with retained ductility of the Core assuring unique Mechanical Properties dreamt by any Civil Engineer. The process involves precise control of Time & Temperature. The red hot bar coming out of the finishing Rolls is rapidly cooled by pressurized water spray forming Martensitic surface layer due to quenching effect which adds strength to the surface while, the core of the Bar remains in the Ferrite-Pearlitic form that means, the core retains the ductility. The bar is automatically tempered and normalized during open cooling process by the remaining heat in the core. So, in total the TMT Bar attains high yield and tensile strength at the same time good bending ability and elongation. TMT Bar has got about 20% higher strength and can save about 15% construction cost in terms of price.

TMT Bar is now highly preferred by the construction engineers because of:

- Higher Mechanical Strength which saves construction cost.

- Ensures better protection and safety against earthquake and cyclone.

- Due to water quenching the surface gives a ferric oxide skin which protects the bar from corrosion.

- Due to better bending and elongation quality process loss is minimum.

See more

See more